| Flaw Detector | Fruit Hardness tester | Rockwell hardness tester | Force gauge | Thickness gauge |

[News] Sterilizer and Distiller

[News] Force Gauge

[Notice] Rockwell Hardness tester

[Event] New Hardness tester on li

[News] We have become the member

[News] UFD610 Ultrasonic Flaw de

[Promote] Fruit Hardness Tester

[News] Force Gauge

[Notice] Rockwell Hardness tester

[Event] New Hardness tester on li

[News] We have become the member

[News] UFD610 Ultrasonic Flaw de

[Promote] Fruit Hardness Tester

[News] Sterilizer and Distiller

[News] Force Gauge

[Notice] Rockwell Hardness tester

[Event] New Hardness tester on li

[News] We have become the member

[News] UFD610 Ultrasonic Flaw de

[Promote] Fruit Hardness Tester

[News] Force Gauge

[Notice] Rockwell Hardness tester

[Event] New Hardness tester on li

[News] We have become the member

[News] UFD610 Ultrasonic Flaw de

[Promote] Fruit Hardness Tester

✤ Home > Products > Automatic Rockwell Hardness > Automatic Rockwell Hardness Tester KHT800-A Details

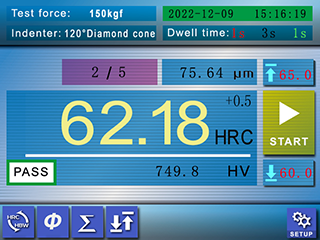

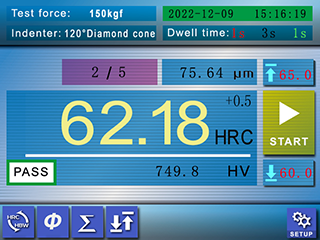

Automatic Rockwell Hardness Tester KHT800-A

[Specifications]:

·In/external testing;

·For metal and plastic;

·Range with 15 scales;

[Automatic Rockwell Hardness Tester KHT800-A Product details]:

Basic functions:

Parameters:

KHT800-A is a new shaped, advanced Automatic Rockwell Hardness Tester, which combine previous function with stable design, easy operation. So it is a popular one in bench hardness tester with highly accurate, automatically, easy installation, quick test’s advantages.

New Featrures:

New Featrures:

- The test force are applied via a closed-loop control unit with a load cell, a DC motor and an electronic measurement and control unit instead of traditional dead weights. The result is highly accurate measurements at all test loads up to 0.5%;

- Simple plug - and - play tech allows for much more quick and easy installation than traditional weights type machine;

- Automated Z-Axis. Just press START key once, entire test process will be finished automatically. Regardless of the the size of the sample, the position of the sample, the distance between the indenter and sample surface. The sample will be auto-lifted to approach the indenter and finishing testing automatically;

- Higher precision than handle wheel lifting/dead weights type machines which can be affected by user interaction;

- Extended dolphin nose allows verticaltest height of 300mm and throat depth of 220mm;

- Integrated casting body with more wide basement leads to permanent stability;

- Built in micro-printer and USB port to PC;

Basic functions:

- Regular Rockwell hardness tester for metal and plastic material;

- Horizontal dolphin nose Indenter is suitable also for internal and external testing;

- Testing on surfaces difficult to reach. Testing internal surface of rings and tubes;

- Provided with many features such as high measuring precision, wide measuring range with 15 Rockwell scales;

- The tester is suitable for testing of carbon steel, alloy steel, cast iron, non ferrous metal;

- Automatic testing cycle: Lifting of part, pre-loading, loading, dwell, unloading, results will be finished automatically;

- Measuring results digitally displaying and can be printed, or transmitted to external computer automatically by USB port;

- Test HR value can be convert to the value of HB, HV, HK and σb value;

- The tester meets all the following standard such as ISO 6508-2, ASTM E18;

Parameters:

- Preload:98.1N /10kgf

- Total calculating test force:588.4N (60kgf), 980.7N (100kgf), 1471N (150kgf)

- Scales:HRA,HRB,HRC,HRD,HRE,HRF, HRG,HRH,HRK,

- HRL,HRM,HRP, HRR,HRS,HRV

- Load dwell duration: 2~50s, choose as be set and restored

- Resolution :0.1HR

- Display:High definition backlight LCD

- Operation:Menu selectable, Membrane keypad

- Upper/lower limits setting & alarming

- Data statistics: Avg., Max., Min., S, R available

- Curved surface correcting automatically

- Memory: Max 400 items of test results stored automatically

- Testing Capacity:300mm (vertical), 220mm (horizontal)

- Dimensions: 690mm×280mm×860mm

- Power supply:AC, 220V/110V, 50~60Hz, 4A

- Net weight:86kg

- Gross weight:120kg

Standard configuration

| Host machine | 1 |

| Standard hardness block for A scale | 1 |

| Standard hardness block for B scale | 1 |

| Standard hardness block for C scale | 3 |

| ball indenter (1/16″) | 1 |

| 120°cone diamond indenter | 1 |

| Mounting screws for indenter | 2 |

| Flat anvil | 1 |

| “V ”shape anvil | 1 |

| Power supply wire | 1 |

| Screwdriver for indenter mounting | 1 |

| Dust cover | 1 |

| Force Gauge | Rockwell Hardness Tester | Roughness Tester | Thickness Gauge | Flaw Detector | Webster Barcol | Hardness Tester | Vibration Tester |

Beijing Lanetech Instruments Co., Ltd. Copyright 2008-2019 All Rights Reserved

Adress:1602 Lingdi,Beiyuan Lu, Chaoyang District,100012 Beijing

E-mail:sales@lanetechworld.com angelajade@126.com

Tel:+86-10-84956391

Hot-Line:+86-10-84956391

Adress:1602 Lingdi,Beiyuan Lu, Chaoyang District,100012 Beijing

E-mail:sales@lanetechworld.com angelajade@126.com

Tel:+86-10-84956391

Hot-Line:+86-10-84956391